What is the current situation of the inductor production industry?

Current Situation of the Inductor Production Industry

I. Introduction

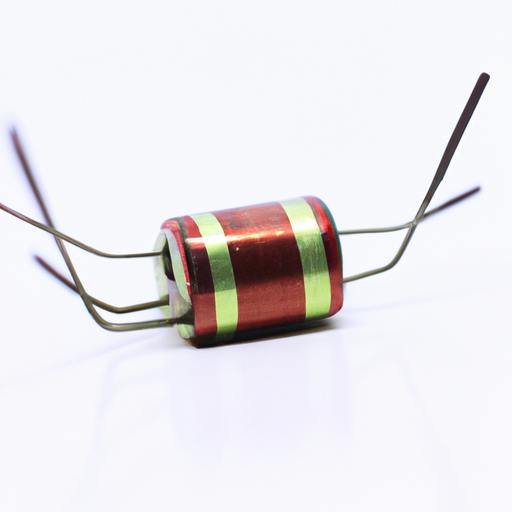

Inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various electronic circuits, including filters, oscillators, and power supplies. The inductor production industry is a vital segment of the global electronics market, supporting a wide range of applications from consumer electronics to automotive systems. This article aims to provide an overview of the current state of the inductor production industry, highlighting market trends, technological advancements, challenges, and future outlook.

II. Overview of the Inductor Market

A. Market Size and Growth Trends

The inductor market has experienced significant growth over the past decade, driven by the increasing demand for electronic devices and advancements in technology. According to recent market research, the global inductor market was valued at approximately $3.5 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of around 5% through 2030. This growth is attributed to the rising adoption of inductors in various sectors, including consumer electronics, automotive, telecommunications, and industrial applications.

B. Key Applications of Inductors

Inductors are utilized in a variety of applications, each contributing to the overall demand for these components:

1. **Consumer Electronics**: Inductors are essential in devices such as smartphones, tablets, and laptops, where they are used in power management circuits and signal processing.

2. **Automotive Industry**: With the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), inductors are increasingly used in power converters, battery management systems, and electric motor drives.

3. **Telecommunications**: Inductors play a critical role in communication devices, including routers and base stations, where they help filter signals and manage power.

4. **Industrial Applications**: In industrial settings, inductors are used in power supplies, motor drives, and various control systems, ensuring efficient operation and energy management.

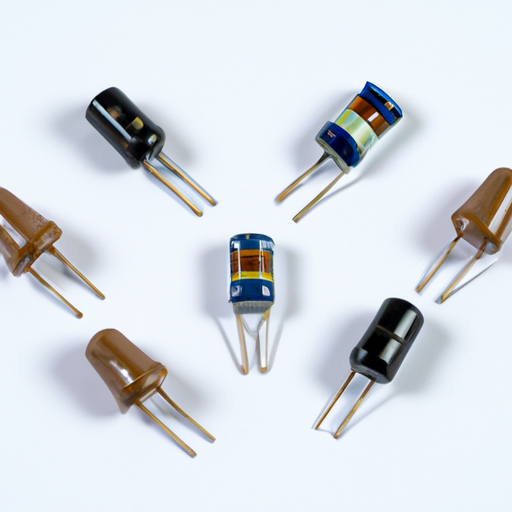

III. Types of Inductors

Inductors come in various types, each designed for specific applications and performance requirements:

A. Air-Core Inductors

These inductors do not use a magnetic core, making them suitable for high-frequency applications. They are often used in RF circuits due to their low losses.

B. Iron-Core Inductors

Iron-core inductors utilize a ferromagnetic core to enhance inductance. They are commonly used in power applications but can suffer from core losses at high frequencies.

C. Ferrite-Core Inductors

Ferrite-core inductors are popular in high-frequency applications due to their low core losses. They are widely used in power supplies and RF applications.

D. Specialty Inductors

Specialty inductors, such as power inductors and RF inductors, are designed for specific applications, offering optimized performance for unique requirements.

E. Comparison of Different Types

When comparing different types of inductors, air-core inductors excel in high-frequency applications, while ferrite-core inductors provide a balance of performance and efficiency. Iron-core inductors are suitable for low-frequency applications but may not perform well in high-frequency scenarios.

IV. Key Players in the Inductor Production Industry

A. Major Manufacturers and Their Market Share

The inductor production industry is characterized by several key players, including:

1. **Murata Manufacturing Co., Ltd.**: A leading manufacturer known for its extensive range of inductors and passive components.

2. **Taiyo Yuden Co., Ltd.**: Specializes in high-performance inductors for various applications, including telecommunications and automotive.

3. **Vishay Intertechnology, Inc.**: Offers a wide range of inductors, including power inductors and RF inductors, catering to diverse markets.

4. **Würth Elektronik GmbH & Co. KG**: Known for its innovative inductor designs and high-quality manufacturing processes.

B. Geographic Distribution of Production Facilities

The production of inductors is geographically diverse, with significant manufacturing facilities located in:

1. **North America**: Home to several leading manufacturers and a growing market for automotive and industrial applications.

2. **Europe**: A hub for advanced technology and innovation, with a focus on high-performance inductors.

3. **Asia-Pacific**: The largest market for inductors, driven by the booming electronics industry in countries like China, Japan, and South Korea.

C. Competitive Landscape and Market Dynamics

The inductor production industry is competitive, with companies constantly innovating to meet the evolving demands of the market. Factors such as pricing, quality, and technological advancements play a crucial role in shaping the competitive landscape.

V. Technological Advancements

A. Innovations in Inductor Design and Materials

Recent advancements in inductor design and materials have led to improved performance and efficiency. Key innovations include:

1. **Miniaturization**: The trend towards smaller electronic devices has driven the development of compact inductors that maintain high performance.

2. **Advanced Materials**: The use of nanocrystalline cores and other advanced materials has enhanced inductance and reduced losses, making inductors more efficient.

B. Impact of Automation and Industry 4.0

The adoption of automation and Industry 4.0 technologies has transformed production processes in the inductor industry. Smart manufacturing techniques, including IoT integration and data analytics, have improved efficiency and reduced production costs.

C. Research and Development Trends

Ongoing research and development efforts are focused on enhancing inductor performance, exploring new materials, and developing innovative designs to meet the demands of emerging technologies.

VI. Challenges Facing the Inductor Production Industry

A. Supply Chain Disruptions

The inductor production industry has faced significant challenges due to supply chain disruptions, particularly during the COVID-19 pandemic. These disruptions have led to delays in production and increased costs.

B. Environmental Regulations and Sustainability Concerns

As environmental regulations become more stringent, manufacturers are under pressure to comply with sustainability standards. This includes adopting eco-friendly materials and processes to minimize environmental impact.

C. Competition from Alternative Technologies

Inductors face competition from alternative technologies, such as capacitors, which can sometimes offer similar functionalities. Manufacturers must continuously innovate to maintain their market position.

VII. Future Outlook

A. Predictions for Market Growth and Demand

The inductor market is expected to continue its growth trajectory, driven by increasing demand for electronic devices, advancements in automotive technology, and the expansion of renewable energy applications.

B. Potential Shifts in Consumer Preferences and Technological Trends

As consumer preferences shift towards more compact and efficient devices, the demand for high-performance inductors will likely increase. Additionally, trends such as electric vehicles and smart technologies will further drive the need for innovative inductor solutions.

C. Strategic Recommendations for Industry Stakeholders

To thrive in the evolving market, industry stakeholders should focus on:

1. **Investing in R&D**: Continuous innovation is essential to meet changing consumer demands and technological advancements.

2. **Enhancing Supply Chain Resilience**: Developing robust supply chain strategies can mitigate disruptions and ensure consistent production.

3. **Emphasizing Sustainability**: Adopting eco-friendly practices and materials will not only comply with regulations but also appeal to environmentally conscious consumers.

VIII. Conclusion

In summary, the inductor production industry is at a pivotal point, characterized by growth, innovation, and challenges. As the demand for electronic devices continues to rise, the importance of inductors in various applications cannot be overstated. Industry stakeholders must remain adaptable and innovative to navigate the complexities of the market and capitalize on emerging opportunities. The future of the inductor production industry looks promising, with advancements in technology and a growing focus on sustainability paving the way for continued success.

IX. References

1. Market Research Reports on Inductor Industry

2. Company Websites of Major Inductor Manufacturers

3. Industry Journals and Publications on Electronics and Components

4. Reports on Supply Chain Trends and Challenges in Electronics Manufacturing

5. Environmental Regulations and Sustainability Practices in Electronics Industry