What components and modules does an inductor unit contain?

What Components and Modules Does an Inductor Unit Contain?

I. Introduction

Inductors are fundamental components in electrical circuits, playing a crucial role in the management of current and energy. Defined as passive electrical devices that store energy in a magnetic field when electrical current flows through them, inductors are essential in various applications, from power supplies to radio frequency (RF) circuits. Understanding the components and modules that make up an inductor unit is vital for engineers and hobbyists alike, as it provides insight into their functionality and performance.

II. Basic Principles of Inductance

A. Explanation of Inductance

Inductance is the property of an electrical conductor that opposes a change in current. When the current flowing through an inductor changes, it induces a voltage in the opposite direction, according to Lenz's Law. This phenomenon is quantified by the inductance value, measured in henries (H), which indicates how effectively an inductor can store energy.

B. Role of Magnetic Fields in Inductors

The operation of an inductor is intrinsically linked to magnetic fields. When current flows through the wire windings of an inductor, it generates a magnetic field around the coil. The strength of this magnetic field is proportional to the amount of current and the number of turns in the coil. This magnetic field is what allows the inductor to store energy and influence the behavior of electrical circuits.

C. Inductance Formula and Units

The inductance (L) of an inductor can be calculated using the formula:

\[ L = \frac{N^2 \cdot \mu \cdot A}{l} \]

Where:

- \( N \) = number of turns in the coil

- \( \mu \) = permeability of the core material

- \( A \) = cross-sectional area of the core

- \( l \) = length of the coil

Inductance is measured in henries (H), with practical inductors often rated in microhenries (µH) or millihenries (mH).

III. Main Components of an Inductor Unit

A. Core Material

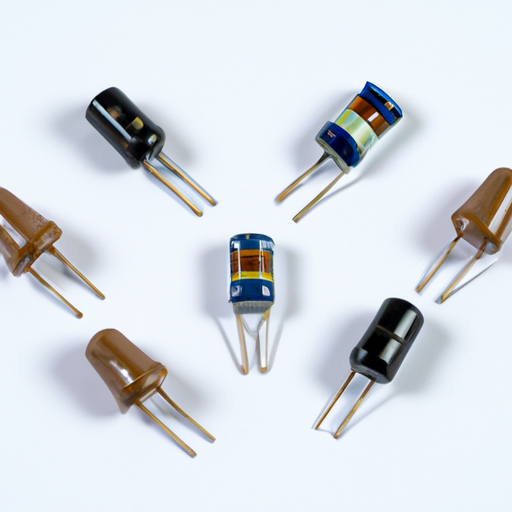

1. Types of Core Materials

The core material of an inductor significantly affects its performance. Common types include:

Air Core: These inductors have no magnetic core, relying solely on the air surrounding the coil. They are typically used in high-frequency applications due to their low losses.

Ferrite Core: Ferrite cores are made from a ceramic compound of iron oxide mixed with other metals. They are popular in RF applications due to their high magnetic permeability and low eddy current losses.

Iron Core: Iron cores provide high inductance values and are often used in power applications. However, they can suffer from significant losses at high frequencies.

2. Impact of Core Material on Inductance

The choice of core material directly influences the inductance value and efficiency of the inductor. Materials with higher permeability can store more magnetic energy, resulting in higher inductance. However, they may also introduce losses, particularly at high frequencies.

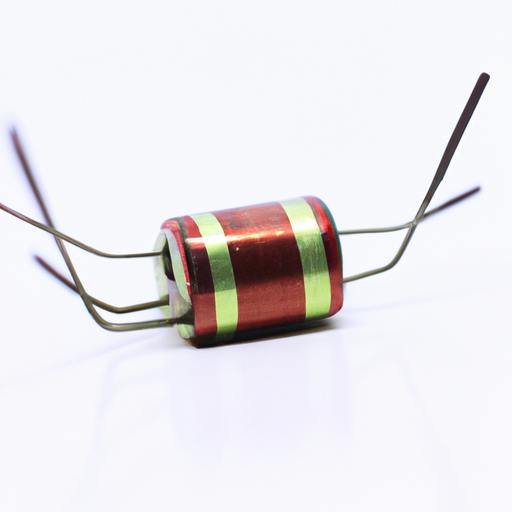

B. Wire Windings

1. Types of Conductors Used

The wire used for the windings of an inductor is typically made from conductive materials such as:

Copper: The most common choice due to its excellent conductivity and availability.

Aluminum: A lighter and less expensive alternative, though it has lower conductivity than copper.

2. Wire Gauge and Its Importance

The gauge of the wire affects the resistance and current-carrying capacity of the inductor. Thicker wires (lower gauge numbers) can handle more current but may take up more space, impacting the overall size of the inductor.

3. Number of Turns and Its Effect on Inductance

The number of turns in the coil is a critical factor in determining the inductance. More turns increase the magnetic field strength and, consequently, the inductance. However, this also increases the resistance and can lead to higher losses.

C. Insulation

1. Purpose of Insulation

Insulation is essential in inductors to prevent short circuits between the wire windings and to protect against electrical interference. It ensures that the inductor operates safely and efficiently.

2. Types of Insulation Materials

Common insulation materials include enamel coatings, plastic films, and paper. The choice of insulation affects the inductor's performance, particularly in high-frequency applications where dielectric losses can occur.

D. Terminals and Connectors

1. Types of Terminals

Inductors can have various terminal types, including solderable leads, screw terminals, and surface-mount pads. The choice of terminal affects how the inductor is integrated into a circuit.

2. Importance of Good Connections

Reliable connections are crucial for the performance of an inductor. Poor connections can lead to increased resistance, heat generation, and reduced efficiency.

IV. Additional Modules in Advanced Inductor Units

A. Shielding

1. Purpose of Shielding

Shielding is used to protect inductors from external electromagnetic interference (EMI) and to prevent the inductor from emitting unwanted electromagnetic fields that could affect nearby components.

2. Types of Shielding Techniques

Common shielding techniques include using conductive enclosures, magnetic shields, and ferrite beads. The choice of shielding depends on the application and the level of interference expected.

B. Damping Mechanisms

1. Importance of Damping in Inductors

Damping is essential to control oscillations and prevent ringing in inductors, particularly in switching applications. Without proper damping, inductors can produce unwanted voltage spikes.

2. Types of Damping Techniques

Damping techniques include the use of resistors in parallel with the inductor, snubber circuits, and ferrite cores designed to minimize resonances.

C. Temperature Compensation

1. Need for Temperature Compensation

Inductors can experience changes in inductance with temperature variations. Temperature compensation is necessary to maintain consistent performance across different operating conditions.

2. Methods of Achieving Temperature Stability

Methods for achieving temperature stability include using materials with low temperature coefficients and designing inductors with specific geometries to minimize thermal effects.

V. Inductor Design Considerations

A. Inductance Value Selection

Selecting the appropriate inductance value is critical for the intended application. Engineers must consider the circuit requirements, including frequency and current levels.

B. Frequency Response

Inductors have frequency-dependent behavior, and their performance can vary significantly across different frequencies. Understanding the frequency response is essential for applications like filtering and RF circuits.

C. Size and Form Factor

The physical size and form factor of an inductor can impact its integration into a circuit. Designers must balance performance with space constraints.

D. Power Rating and Efficiency

Inductors must be rated for the power levels they will encounter in operation. Efficiency is also a key consideration, as higher losses can lead to overheating and reduced performance.

VI. Applications of Inductors

A. Power Supply Circuits

Inductors are commonly used in power supply circuits for energy storage, filtering, and voltage regulation. They help smooth out fluctuations in current and voltage.

B. RF Applications

In RF circuits, inductors are used for tuning, filtering, and impedance matching. Their ability to store energy in a magnetic field makes them ideal for these applications.

C. Filtering and Energy Storage

Inductors play a vital role in filtering applications, helping to remove unwanted frequencies from signals. They are also used in energy storage systems, such as in switch-mode power supplies.

D. Inductors in Transformers

Inductors are integral components of transformers, where they work together to transfer energy between circuits through electromagnetic induction.

VII. Conclusion

In summary, inductors are complex devices composed of various components and modules, each playing a critical role in their functionality. Understanding these components—such as core materials, wire windings, insulation, and additional modules—provides valuable insights into their operation and applications. As technology advances, the design and application of inductors continue to evolve, making it essential for engineers to stay informed about the latest trends and innovations in inductor technology.

VIII. References

A. Suggested Reading Materials

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Inductor Design and Applications" by John Smith

B. Relevant Journals and Articles

- IEEE Transactions on Power Electronics

- Journal of Electrical Engineering & Technology

C. Online Resources for Further Learning

- Electronics Tutorials (www.electronicstutorials.com)

- All About Circuits (www.allaboutcircuits.com)

This comprehensive overview of inductors and their components provides a solid foundation for understanding their role in electrical engineering and their applications in modern technology.