What are the important product categories of inductor manufacturers?

Important Product Categories of Inductor Manufacturers

I. Introduction

Inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various electronic circuits, serving functions such as filtering, energy storage, and signal processing. As the demand for advanced electronic devices continues to grow, the role of inductor manufacturers becomes increasingly significant. This blog post will explore the important product categories of inductor manufacturers, highlighting their types, applications, and innovations in the industry.

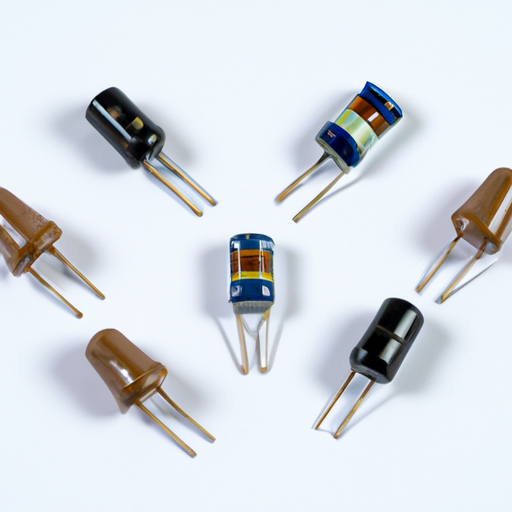

II. Types of Inductors

Inductors come in various types, each designed for specific applications and performance characteristics. Understanding these types is essential for selecting the right inductor for a given application.

A. Air Core Inductors

Air core inductors are made without a magnetic core, relying solely on the air surrounding the coil to create inductance.

1. **Definition and Characteristics**: These inductors are characterized by their low inductance values and high Q factors, which make them suitable for high-frequency applications. They are less prone to saturation and have minimal losses due to the absence of a core material.

2. **Applications**: Air core inductors are commonly used in radio frequency (RF) applications, such as antennas and RF amplifiers, where high efficiency and low distortion are critical.

B. Iron Core Inductors

Iron core inductors utilize an iron core to enhance inductance by concentrating the magnetic field.

1. **Definition and Characteristics**: These inductors have higher inductance values compared to air core inductors and are capable of handling larger currents. However, they may suffer from core losses due to hysteresis and eddy currents.

2. **Applications**: Iron core inductors are often used in power supply circuits, transformers, and audio equipment, where higher inductance and current handling are required.

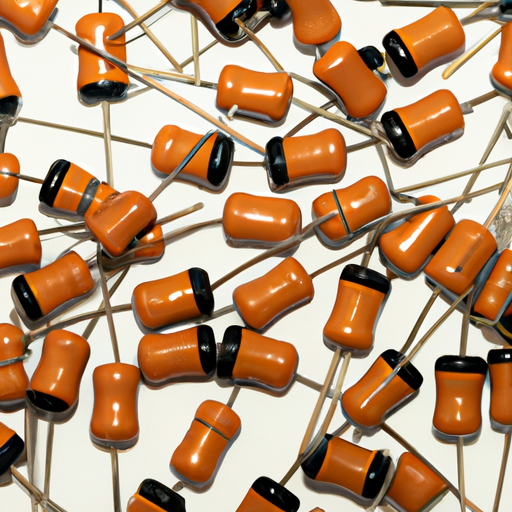

C. Ferrite Core Inductors

Ferrite core inductors use ferrite materials, which are ceramic compounds made from iron oxide and other metals.

1. **Definition and Characteristics**: Ferrite cores provide high magnetic permeability, allowing for compact designs with high inductance values. They are less prone to core losses than iron cores, making them suitable for high-frequency applications.

2. **Applications**: Ferrite core inductors are widely used in switch-mode power supplies, RF applications, and telecommunications equipment.

D. Toroidal Inductors

Toroidal inductors are shaped like a doughnut, with the wire wound around a toroidal core.

1. **Definition and Characteristics**: The toroidal shape minimizes electromagnetic interference (EMI) and provides a high inductance-to-size ratio. They are efficient and have low core losses.

2. **Applications**: These inductors are commonly found in power supplies, audio equipment, and various electronic devices where space is a constraint.

E. Choke Inductors

Choke inductors are designed to block high-frequency AC signals while allowing DC or low-frequency signals to pass.

1. **Definition and Characteristics**: Chokes can be air core, iron core, or ferrite core, depending on their application. They are characterized by their ability to filter out unwanted frequencies.

2. **Applications**: Choke inductors are used in power supply circuits, audio systems, and radio transmitters to prevent interference and ensure signal integrity.

III. Specialty Inductors

In addition to standard inductors, there are specialty inductors designed for specific applications and performance requirements.

A. Power Inductors

Power inductors are designed to handle high currents and are optimized for power electronics.

1. **Definition and Characteristics**: These inductors typically have low DC resistance and high saturation current ratings, making them suitable for power management applications.

2. **Applications in Power Electronics**: Power inductors are commonly used in DC-DC converters, voltage regulators, and energy storage systems.

B. RF Inductors

RF inductors are specifically designed for radio frequency applications.

1. **Definition and Characteristics**: These inductors have low parasitic capacitance and are optimized for high-frequency performance.

2. **Applications in Radio Frequency Circuits**: RF inductors are used in RF amplifiers, oscillators, and filters, where precise inductance values are critical for signal integrity.

C. SMD Inductors (Surface Mount Device)

SMD inductors are designed for surface mounting on printed circuit boards (PCBs).

1. **Definition and Characteristics**: These inductors are compact and designed for automated assembly processes, making them ideal for modern electronic devices.

2. **Applications in Compact Electronic Devices**: SMD inductors are commonly found in smartphones, tablets, and other compact devices where space is limited.

D. High-Frequency Inductors

High-frequency inductors are optimized for performance at elevated frequencies.

1. **Definition and Characteristics**: These inductors are designed to minimize losses and maintain performance at high frequencies, often using specialized materials and construction techniques.

2. **Applications in High-Speed Circuits**: High-frequency inductors are used in telecommunications, data communication, and high-speed digital circuits.

IV. Inductor Components and Accessories

Inductor performance can be influenced by various components and accessories that enhance their functionality.

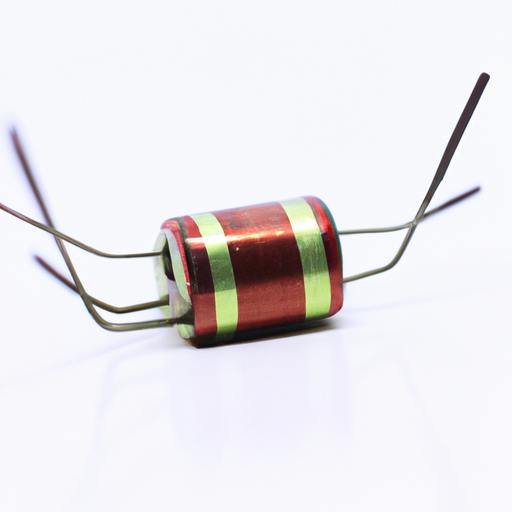

A. Inductor Coils

Inductor coils are the primary component of inductors, and their design significantly impacts performance.

1. **Types and Materials**: Coils can be made from copper, aluminum, or other conductive materials, and their design can vary in terms of winding techniques and number of turns.

2. **Importance in Inductor Performance**: The choice of coil material and design affects the inductor's resistance, inductance value, and overall efficiency.

B. Inductor Shields

Inductor shields are used to reduce electromagnetic interference and improve performance.

1. **Purpose and Benefits**: Shields help to contain the magnetic field and prevent interference with nearby components, enhancing overall circuit performance.

2. **Types of Shielding Materials**: Common shielding materials include ferrite, copper, and aluminum, each offering different levels of effectiveness.

C. Inductor Mounting Hardware

Proper mounting hardware is essential for the installation and performance of inductors.

1. **Types of Mounting Options**: Inductors can be mounted using through-hole, surface mount, or bracket mounting techniques, depending on the application.

2. **Importance for Installation and Performance**: Proper mounting ensures stability, reduces mechanical stress, and enhances thermal performance.

V. Custom Inductor Solutions

Customization is often necessary to meet specific application requirements.

A. Importance of Customization in Inductors

Custom inductors allow manufacturers to tailor designs to meet unique specifications, ensuring optimal performance in specific applications.

B. Factors Influencing Custom Inductor Design

1. **Size and Form Factor**: The physical dimensions of the inductor must fit within the constraints of the device it will be used in.

2. **Inductance Value and Tolerance**: Custom inductors can be designed to achieve specific inductance values with precise tolerances.

3. **Operating Temperature and Environment**: Inductors may need to withstand specific environmental conditions, such as high temperatures or humidity.

C. Examples of Industries Requiring Custom Inductors

1. **Automotive**: Custom inductors are used in electric vehicles and advanced driver-assistance systems (ADAS).

2. **Telecommunications**: Custom inductors are essential for high-performance communication systems.

3. **Medical Devices**: Custom inductors are used in medical equipment, where reliability and precision are critical.

VI. Trends and Innovations in Inductor Manufacturing

The inductor manufacturing industry is continually evolving, driven by advancements in technology and changing market demands.

A. Advances in Materials and Technology

Innovations in materials, such as the development of new ferrite compounds and conductive materials, are enhancing inductor performance and efficiency.

B. Miniaturization and Its Impact on Design

As electronic devices become smaller, the demand for compact inductors has increased, leading to innovative designs that maintain performance while reducing size.

C. Sustainability and Eco-Friendly Manufacturing Practices

Manufacturers are increasingly focusing on sustainable practices, such as using recyclable materials and reducing waste in the production process.

VII. Conclusion

Inductors are vital components in modern electronics, and understanding the various product categories offered by inductor manufacturers is essential for selecting the right component for specific applications. From air core to specialty inductors, each type serves a unique purpose in electronic circuits. As technology continues to advance, the future of inductor manufacturing looks promising, with innovations in materials, design, and sustainability paving the way for more efficient and effective inductors. Ultimately, inductors will continue to play a crucial role in shaping the future of electronics, ensuring reliable performance in an ever-evolving technological landscape.