What are the product characteristics of wire wound inductors?

What are the Product Characteristics of Wire Wound Inductors?

I. Introduction

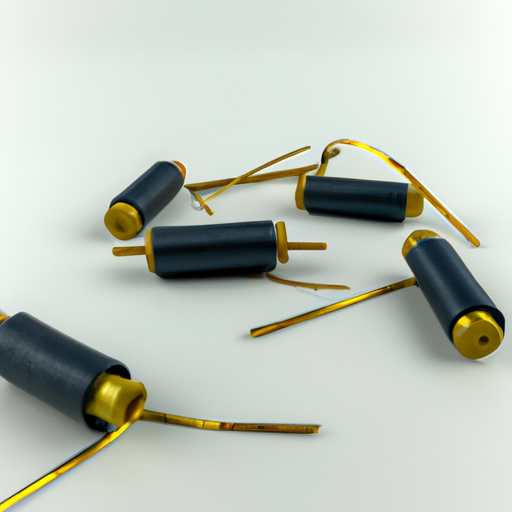

A. Definition of Wire Wound Inductors

Wire wound inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They are constructed by winding a conductive wire around a core material, which enhances their inductive properties. These inductors are widely used in various electronic applications due to their ability to manage current and voltage levels effectively.

B. Importance of Inductors in Electronic Circuits

Inductors play a crucial role in electronic circuits, serving functions such as filtering, energy storage, and signal processing. They are essential in power supply circuits, radio frequency (RF) applications, and audio equipment, among others. Their ability to oppose changes in current makes them vital for maintaining stable operation in electronic devices.

C. Purpose of the Article

This article aims to explore the product characteristics of wire wound inductors, including their construction, key features, performance characteristics, applications, and the advantages and disadvantages associated with their use.

II. Basic Principles of Inductance

A. Explanation of Inductance

Inductance is the property of an electrical conductor that opposes changes in current. When current flows through a wire, it generates a magnetic field around it. If the current changes, the magnetic field also changes, inducing a voltage in the wire that opposes the change in current. This phenomenon is known as self-induction.

B. Role of Inductors in Electrical Circuits

Inductors are used to store energy in the magnetic field created by the current flowing through them. They can smooth out fluctuations in current, filter out high-frequency noise, and store energy for later use. This makes them essential components in power supplies, oscillators, and various signal processing applications.

C. Overview of Wire Wound Inductor Functionality

Wire wound inductors function by utilizing the principles of inductance. The wire winding increases the inductance value, while the core material enhances the magnetic field. The design and construction of these inductors determine their performance characteristics, making them suitable for specific applications.

III. Construction of Wire Wound Inductors

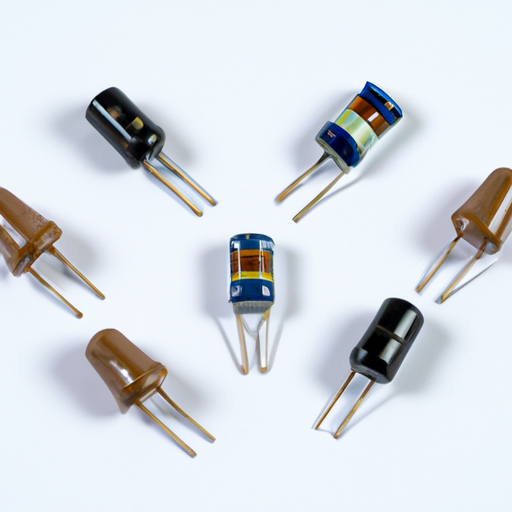

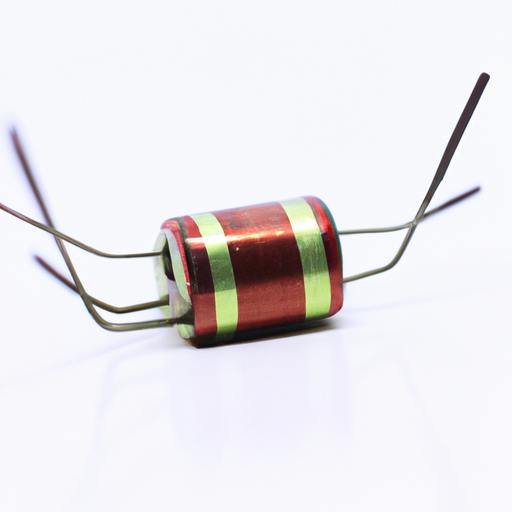

A. Core Materials

The core material of a wire wound inductor significantly influences its performance. Common core materials include:

1. **Air Core**: These inductors have no core material, relying solely on the wire's magnetic field. They are lightweight and have a high self-resonant frequency but are less efficient for high inductance values.

2. **Ferrite Core**: Ferrite cores are made from a ceramic material that is magnetically permeable. They provide high inductance values and are commonly used in RF applications due to their low losses at high frequencies.

3. **Iron Core**: Iron cores offer high inductance and are suitable for low-frequency applications. However, they can suffer from core losses due to hysteresis and eddy currents.

B. Wire Types

The type of wire used in the construction of wire wound inductors also affects their performance:

1. **Copper Wire**: Copper is the most common choice due to its excellent conductivity and low resistance.

2. **Aluminum Wire**: While less conductive than copper, aluminum is lighter and can be more cost-effective for certain applications.

3. **Enamel Coated Wire**: This type of wire is coated with an insulating layer, preventing short circuits between turns of the wire and allowing for tighter winding.

C. Winding Techniques

The winding technique used in constructing wire wound inductors can vary:

1. **Single Layer Winding**: This technique involves winding the wire in a single layer around the core, resulting in a compact design.

2. **Multi-Layer Winding**: Multiple layers of wire are wound on top of each other, increasing the inductance value but also the size of the inductor.

3. **Toroidal Winding**: The wire is wound around a toroidal (doughnut-shaped) core, which minimizes electromagnetic interference (EMI) and enhances efficiency.

IV. Key Product Characteristics

A. Inductance Value

1. Measurement Units (Henries)

Inductance is measured in henries (H), with common values ranging from microhenries (µH) to millihenries (mH) for wire wound inductors. The inductance value determines how much energy the inductor can store.

2. Factors Affecting Inductance

The inductance value is influenced by several factors, including the number of wire turns, the core material, and the geometry of the inductor. Increasing the number of turns or using a more permeable core material will generally increase the inductance.

B. Current Rating

1. Definition and Importance

The current rating of an inductor indicates the maximum current it can handle without overheating or saturating. Exceeding this rating can lead to performance degradation or failure.

2. Saturation Current

Saturation current is the point at which the inductor can no longer store additional energy in its magnetic field, leading to a significant drop in inductance. Understanding this characteristic is crucial for ensuring reliable operation in circuits.

C. DC Resistance (DCR)

1. Impact on Performance

DC resistance (DCR) refers to the resistance of the wire used in the inductor. A lower DCR results in less power loss and improved efficiency, making it an important characteristic for high-performance applications.

2. Measurement Techniques

DCR can be measured using a multimeter or specialized equipment designed for low-resistance measurements. Accurate measurement is essential for assessing the inductor's performance.

D. Quality Factor (Q)

1. Definition and Significance

The quality factor (Q) is a measure of an inductor's efficiency, defined as the ratio of its inductive reactance to its resistance at a specific frequency. A higher Q indicates lower energy losses and better performance.

2. Factors Influencing Q Factor

The Q factor is influenced by the inductor's construction, core material, and operating frequency. Designers often aim for a high Q factor in applications where efficiency is critical.

E. Self-Resonant Frequency (SRF)

1. Explanation of SRF

The self-resonant frequency (SRF) is the frequency at which the inductive reactance and capacitive reactance of the inductor are equal, causing it to resonate. Beyond this frequency, the inductor behaves more like a capacitor.

2. Importance in Circuit Design

Understanding the SRF is essential for circuit designers, as operating an inductor above its SRF can lead to unintended behavior and reduced performance.

F. Temperature Coefficient

1. Definition and Relevance

The temperature coefficient indicates how the inductance value changes with temperature. A low temperature coefficient is desirable for maintaining consistent performance across varying environmental conditions.

2. Impact on Performance

Temperature variations can affect the inductance and resistance of wire wound inductors, impacting their performance in sensitive applications.

V. Performance Characteristics

A. Frequency Response

1. Behavior at Different Frequencies

Wire wound inductors exhibit different behaviors at various frequencies. At low frequencies, they act as effective energy storage devices, while at high frequencies, they may experience losses due to parasitic capacitance.

2. Applications in RF Circuits

In RF applications, wire wound inductors are used for filtering and tuning circuits. Their frequency response characteristics are critical for ensuring optimal performance in these applications.

B. Power Handling Capability

1. Thermal Management

Effective thermal management is essential for wire wound inductors, as excessive heat can lead to performance degradation and failure. Proper design and materials can help dissipate heat effectively.

2. Effects of Overheating

Overheating can cause changes in inductance, increased DCR, and even physical damage to the inductor. Understanding the power handling capability is crucial for reliable circuit design.

C. Magnetic Shielding

1. Importance in Reducing EMI

Magnetic shielding is vital for reducing electromagnetic interference (EMI) in sensitive applications. Wire wound inductors can be designed with shielding to minimize the impact of external magnetic fields.

2. Techniques for Shielding

Common shielding techniques include using conductive enclosures or incorporating ferrite materials into the inductor design. These methods help protect the inductor's performance in noisy environments.

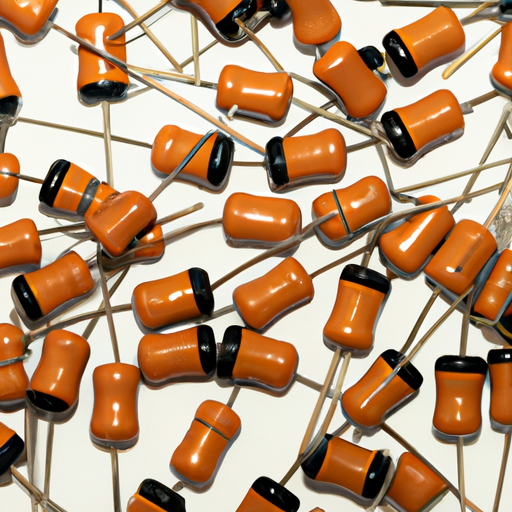

VI. Applications of Wire Wound Inductors

Wire wound inductors are versatile components used in various applications, including:

A. Power Supply Circuits

In power supply circuits, wire wound inductors help filter out noise and stabilize voltage levels, ensuring reliable operation of electronic devices.

B. RF Applications

In RF circuits, these inductors are used for tuning and filtering signals, playing a crucial role in communication systems.

C. Audio Equipment

Wire wound inductors are employed in audio equipment to manage signal integrity and reduce distortion, enhancing sound quality.

D. Automotive Electronics

In automotive applications, wire wound inductors are used in power management systems, sensors, and communication devices, contributing to the overall functionality of modern vehicles.

E. Telecommunications

Telecommunications equipment relies on wire wound inductors for signal processing and filtering, ensuring clear and reliable communication.

VII. Advantages and Disadvantages

A. Advantages

1. High Inductance Values

Wire wound inductors can achieve high inductance values, making them suitable for a wide range of applications.

2. Customizability

These inductors can be customized in terms of size, inductance value, and core material, allowing for tailored solutions to meet specific requirements.

3. Robustness

Wire wound inductors are generally robust and can withstand harsh operating conditions, making them reliable components in various applications.

B. Disadvantages

1. Size and Weight

Wire wound inductors can be larger and heavier than other types of inductors, which may be a consideration in space-constrained applications.

2. Cost Considerations

The cost of wire wound inductors can be higher than other types, particularly for custom designs or those with specialized materials.

3. Limited Frequency Range

While wire wound inductors perform well at certain frequencies, they may not be suitable for very high-frequency applications due to parasitic effects.

VIII. Conclusion

A. Summary of Key Points

Wire wound inductors are essential components in electronic circuits, offering high inductance values, customizability, and robustness. Their construction, key characteristics, and performance traits make them suitable for a wide range of applications, from power supplies to telecommunications.

B. Future Trends in Wire Wound Inductor Technology

As technology advances, wire wound inductors are likely to see improvements in materials, design techniques, and manufacturing processes, leading to enhanced performance and efficiency.

C. Final Thoughts on Selection and Use

When selecting wire wound inductors for specific applications, it is crucial to consider their key characteristics, performance traits, and the specific requirements of the circuit. Understanding these factors will ensure optimal performance and reliability in electronic designs.

IX. References

A. Academic Journals

- IEEE Transactions on Power Electronics

- Journal of Applied Physics

B. Industry Standards

- IEC 60068-2-6: Environmental Testing

- IPC-2221: Generic Standard on Printed Board Design

C. Manufacturer Specifications

- Datasheets from leading inductor manufacturers

- Application notes from electronic component suppliers

---

This blog post provides a comprehensive overview of wire wound inductors, detailing their construction, characteristics, performance, and applications. By understanding these aspects, readers can make informed decisions when selecting inductors for their electronic designs.