What are the product standards for series capacitors?

What are the Product Standards for Series Capacitors?

I. Introduction

A. Definition of Series Capacitors

Series capacitors are electrical components that store and release electrical energy in a circuit. They are connected in series with other circuit elements, which allows them to influence the overall impedance and phase angle of the circuit. By doing so, they can improve power factor, reduce voltage fluctuations, and enhance the performance of electrical systems.

B. Importance of Product Standards

Product standards are essential in ensuring that series capacitors function safely and effectively in various applications. These standards provide guidelines for design, manufacturing, testing, and performance, ensuring that capacitors meet specific safety and reliability criteria. Adhering to these standards not only protects consumers but also fosters innovation and competition in the industry.

C. Overview of the Document Structure

This blog post will explore the fundamental principles of series capacitors, the importance of product standards, key standards applicable to series capacitors, testing and certification processes, challenges in meeting these standards, and future trends in capacitor technology.

II. Understanding Series Capacitors

A. Basic Principles of Series Capacitors

1. Functionality in Electrical Circuits

In electrical circuits, series capacitors are used to store energy in an electric field. When voltage is applied, the capacitor charges up, and when the voltage is removed, it discharges, releasing the stored energy. This functionality is crucial in applications such as power factor correction, energy storage systems, and filtering in power electronics.

2. Applications in Various Industries

Series capacitors find applications across multiple industries, including telecommunications, automotive, renewable energy, and consumer electronics. In telecommunications, they are used for signal coupling and decoupling, while in automotive applications, they help manage power distribution and improve efficiency.

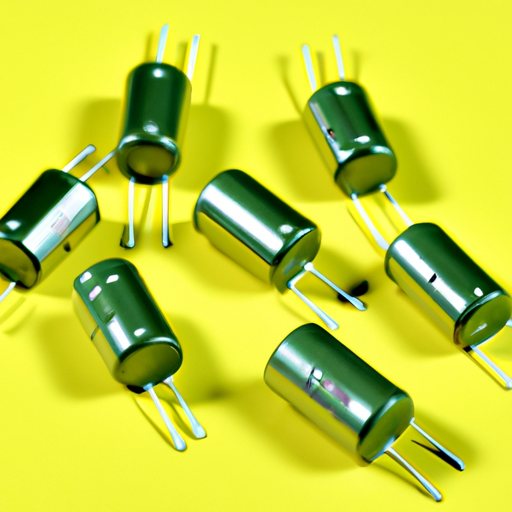

B. Types of Series Capacitors

1. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that offer high capacitance values in a compact size. They are commonly used in power supply circuits and energy storage applications. However, they have limitations in terms of voltage and temperature ratings.

2. Ceramic Capacitors

Ceramic capacitors are non-polarized and are known for their stability and reliability. They are widely used in high-frequency applications and are available in various capacitance values. Their small size and low cost make them a popular choice in consumer electronics.

3. Film Capacitors

Film capacitors are made from thin plastic films and are known for their excellent performance in terms of stability and low losses. They are often used in applications requiring high voltage and high-frequency performance, such as in audio equipment and power electronics.

III. Importance of Product Standards

A. Ensuring Safety and Reliability

Product standards play a critical role in ensuring the safety and reliability of series capacitors. By adhering to established standards, manufacturers can minimize the risk of failures that could lead to hazardous situations, such as electrical fires or equipment damage.

B. Facilitating Interoperability

Standards facilitate interoperability between different manufacturers' products. This is particularly important in industries where components from various suppliers must work together seamlessly. By following common standards, manufacturers can ensure that their products are compatible with others in the market.

C. Enhancing Performance and Efficiency

Product standards help enhance the performance and efficiency of series capacitors. By setting benchmarks for performance, manufacturers are encouraged to innovate and improve their products, leading to better energy efficiency and overall performance in electrical systems.

D. Regulatory Compliance

Compliance with product standards is often a legal requirement in many jurisdictions. Manufacturers must ensure that their products meet these standards to avoid legal repercussions and to gain market access. This compliance also builds consumer trust in the products they purchase.

IV. Key Product Standards for Series Capacitors

A. International Standards

1. IEC (International Electrotechnical Commission) Standards

The IEC sets several important standards for series capacitors, including:

IEC 60384: This standard covers fixed capacitors for use in electronic equipment, specifying requirements for safety, performance, and testing methods.

IEC 61071: This standard pertains to capacitors for power electronics, focusing on their performance in high-power applications.

2. ISO (International Organization for Standardization) Standards

ISO standards also play a role in the manufacturing and quality assurance processes for series capacitors, ensuring that manufacturers adhere to best practices in production and management.

B. National Standards

1. ANSI (American National Standards Institute)

In the United States, ANSI develops standards that govern the performance and safety of electrical components, including series capacitors. Compliance with ANSI standards is often required for products sold in the U.S. market.

2. UL (Underwriters Laboratories) Standards

UL standards focus on safety and performance testing for electrical components. Series capacitors that meet UL standards are recognized for their safety and reliability, making them more appealing to consumers and manufacturers alike.

C. Industry-Specific Standards

1. Automotive Standards (e.g., AEC-Q200)

In the automotive industry, series capacitors must meet specific standards such as AEC-Q200, which outlines the reliability and performance requirements for electronic components used in automotive applications.

2. Telecommunications Standards

Telecommunications standards ensure that series capacitors used in communication devices meet the necessary performance criteria for signal integrity and reliability.

V. Testing and Certification Processes

A. Overview of Testing Procedures

1. Electrical Testing

Electrical testing evaluates the performance of series capacitors under various voltage and frequency conditions. This testing ensures that capacitors can handle the electrical demands of their intended applications.

2. Environmental Testing

Environmental testing assesses how series capacitors perform under different environmental conditions, such as temperature, humidity, and vibration. This testing is crucial for applications in harsh environments, such as automotive and aerospace.

3. Mechanical Testing

Mechanical testing evaluates the physical durability of series capacitors, ensuring they can withstand mechanical stress and strain during operation.

B. Certification Bodies

1. Role of Certification in Product Standards

Certification bodies play a vital role in verifying that series capacitors meet established standards. They conduct testing and evaluation, providing manufacturers with the necessary certifications to demonstrate compliance.

2. Examples of Recognized Certification Organizations

Some recognized certification organizations include UL, CSA (Canadian Standards Association), and TUV Rheinland. These organizations provide independent verification of product compliance with safety and performance standards.

VI. Challenges in Meeting Product Standards

A. Technological Advancements

Rapid technological advancements can make it challenging for manufacturers to keep up with evolving standards. As new materials and technologies emerge, standards must be updated to reflect these changes, requiring manufacturers to adapt quickly.

B. Variability in Manufacturing Processes

Variability in manufacturing processes can lead to inconsistencies in product quality. Manufacturers must implement strict quality control measures to ensure that their products consistently meet established standards.

C. Global Market Considerations

In a global market, manufacturers must navigate different standards and regulations in various countries. This complexity can create challenges in ensuring compliance and may require additional resources for testing and certification.

VII. Future Trends in Series Capacitor Standards

A. Innovations in Capacitor Technology

As technology continues to evolve, innovations in capacitor design and materials are expected. These advancements may lead to new standards that address the performance and efficiency of next-generation capacitors.

B. Evolving Regulatory Landscape

The regulatory landscape for electrical components is continually changing. Manufacturers must stay informed about new regulations and standards to ensure compliance and maintain market access.

C. Sustainability and Environmental Considerations

Sustainability is becoming increasingly important in the manufacturing of electrical components. Future standards may focus on environmentally friendly materials and production processes, promoting a more sustainable approach to capacitor manufacturing.

VIII. Conclusion

A. Recap of the Importance of Product Standards

Product standards for series capacitors are essential for ensuring safety, reliability, and performance in electrical systems. They provide a framework for manufacturers to follow, promoting innovation and consumer trust.

B. The Role of Standards in Advancing Technology

Standards play a crucial role in advancing technology by setting benchmarks for performance and safety. As the industry evolves, adherence to these standards will be vital for manufacturers looking to remain competitive.

C. Call to Action for Manufacturers and Engineers

Manufacturers and engineers must prioritize compliance with product standards to ensure the safety and reliability of series capacitors. By staying informed about evolving standards and investing in quality control, they can contribute to the advancement of technology and the overall improvement of electrical systems.

IX. References

A. List of Relevant Standards and Guidelines

- IEC 60384 - Fixed Capacitors for Use in Electronic Equipment

- IEC 61071 - Capacitors for Power Electronics

- AEC-Q200 - Automotive Electronics Council Standard

B. Suggested Further Reading on Series Capacitors and Standards

- "Capacitor Technology: A Comprehensive Guide" by John Smith

- "Understanding Electrical Standards: A Practical Approach" by Jane Doe

This blog post provides a comprehensive overview of the product standards for series capacitors, highlighting their importance, key standards, testing processes, challenges, and future trends. By understanding these aspects, manufacturers and engineers can better navigate the complexities of the industry and contribute to the advancement of technology.