Latest regenerative resistor specifications

Latest Regenerative Resistor Specifications

I. Introduction

In the realm of electrical engineering, regenerative resistors play a pivotal role in enhancing the efficiency and performance of various systems. These components are designed to manage energy dissipation effectively, making them essential in applications ranging from automotive systems to renewable energy technologies. This article aims to provide an overview of the latest specifications and advancements in regenerative resistors, highlighting their significance in modern applications.

II. Overview of Regenerative Resistors

A. Explanation of Regenerative Resistors and Their Function

Regenerative resistors are specialized components that convert electrical energy into heat, allowing for energy dissipation in a controlled manner. Unlike traditional resistors, regenerative resistors are designed to handle higher power levels and are often used in applications where energy recovery is crucial. They are integral to systems that require braking or energy recovery, such as electric vehicles and renewable energy systems.

B. Historical Context and Evolution of Regenerative Resistor Technology

The technology behind regenerative resistors has evolved significantly over the years. Initially, resistors were simple components with limited capabilities. However, advancements in materials science and engineering have led to the development of high-performance resistors that can withstand extreme conditions and deliver superior performance. This evolution has been driven by the increasing demand for energy-efficient solutions in various industries.

C. Key Applications in Various Industries

Regenerative resistors find applications in a wide range of industries, including:

Automotive: Used in electric and hybrid vehicles for regenerative braking systems.

Renewable Energy: Essential in wind turbines and solar inverters for energy management.

Electronics: Employed in power supplies and electronic circuits to manage energy dissipation.

III. Key Specifications of Regenerative Resistors

A. Resistance Range

1. Typical Resistance Values

Regenerative resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms. The choice of resistance depends on the specific application and the desired energy dissipation characteristics.

2. Factors Influencing Resistance Selection

When selecting a regenerative resistor, factors such as load requirements, voltage levels, and thermal management must be considered. The resistance value directly impacts the power dissipation and efficiency of the system.

B. Power Rating

1. Definition and Importance of Power Rating

The power rating of a regenerative resistor indicates the maximum amount of power it can handle without overheating. This specification is crucial for ensuring the reliability and longevity of the component in high-power applications.

2. Latest Advancements in Power Handling Capabilities

Recent advancements have led to the development of regenerative resistors with significantly higher power ratings. Innovations in materials and construction techniques have enabled resistors to handle power levels exceeding several kilowatts, making them suitable for demanding applications.

C. Temperature Coefficient

1. Explanation of Temperature Coefficient and Its Significance

The temperature coefficient of a resistor indicates how its resistance changes with temperature. A low temperature coefficient is desirable, as it ensures stable performance across varying temperature conditions.

2. Current Trends in Temperature Stability

Manufacturers are increasingly focusing on producing resistors with improved temperature stability. This is particularly important in applications where temperature fluctuations can impact performance, such as in automotive and aerospace systems.

D. Tolerance Levels

1. Definition of Tolerance in Resistors

Tolerance refers to the allowable deviation from the specified resistance value. It is expressed as a percentage and indicates the precision of the resistor.

2. Industry Standards and Latest Specifications

The latest specifications for regenerative resistors often adhere to industry standards, such as those set by the International Electrotechnical Commission (IEC). These standards ensure that resistors meet specific performance criteria, enhancing their reliability in critical applications.

E. Voltage Rating

1. Importance of Voltage Rating in Regenerative Applications

The voltage rating of a regenerative resistor indicates the maximum voltage it can withstand without failure. This specification is vital in applications where high voltages are present, such as in electric vehicles and industrial machinery.

2. Recent Developments in High-Voltage Resistors

Recent innovations have led to the creation of high-voltage regenerative resistors capable of handling voltages exceeding several kilovolts. These advancements are crucial for applications in power electronics and renewable energy systems.

IV. Materials and Construction

A. Common Materials Used in Regenerative Resistors

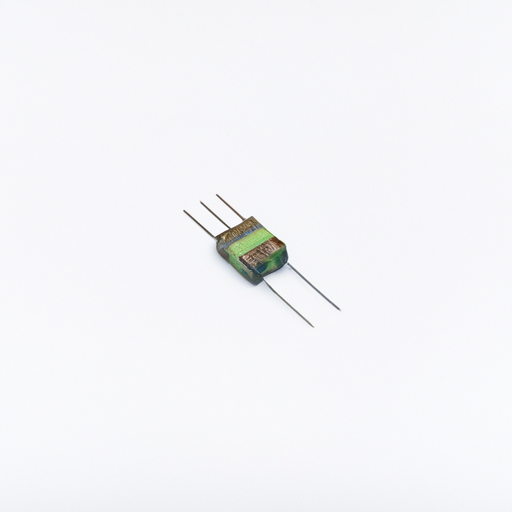

1. Metal Film, Carbon Film, Wire-Wound, etc.

Regenerative resistors are constructed from various materials, each offering distinct advantages and disadvantages. Common materials include:

Metal Film: Known for high precision and stability.

Carbon Film: Offers good performance at a lower cost.

Wire-Wound: Suitable for high-power applications due to their robust construction.

2. Advantages and Disadvantages of Each Material

Each material has its own set of characteristics. For instance, metal film resistors provide excellent temperature stability but may have lower power ratings compared to wire-wound resistors, which excel in high-power applications but may have higher noise levels.

B. Innovations in Materials for Enhanced Performance

1. Composite Materials

The use of composite materials in regenerative resistors is gaining traction. These materials combine the benefits of different substances, resulting in resistors with improved performance characteristics, such as enhanced thermal conductivity and reduced weight.

2. Nanotechnology Applications

Nanotechnology is also making its mark in the development of regenerative resistors. By manipulating materials at the nanoscale, manufacturers can create resistors with superior performance, including increased power handling and reduced size.

V. Performance Characteristics

A. Thermal Management

1. Importance of Heat Dissipation in Regenerative Resistors

Effective thermal management is crucial for the performance and longevity of regenerative resistors. Excessive heat can lead to failure, making it essential to design resistors that can dissipate heat efficiently.

2. Latest Cooling Technologies and Designs

Innovative cooling technologies, such as heat sinks and active cooling systems, are being integrated into regenerative resistor designs. These advancements help maintain optimal operating temperatures, enhancing reliability and performance.

B. Reliability and Longevity

1. Factors Affecting the Lifespan of Regenerative Resistors

The lifespan of regenerative resistors is influenced by factors such as operating temperature, power levels, and environmental conditions. Understanding these factors is essential for selecting the right resistor for a specific application.

2. Recent Advancements in Durability and Reliability Testing

Manufacturers are investing in advanced testing methods to evaluate the durability and reliability of regenerative resistors. These tests simulate real-world conditions, ensuring that resistors can withstand the rigors of their intended applications.

C. Noise Performance

1. Understanding Noise in Resistive Components

Noise in resistive components can adversely affect the performance of electronic systems. It is essential to understand the sources of noise and how they impact overall system performance.

2. Techniques to Minimize Noise in Regenerative Resistors

Recent advancements in design and materials have led to techniques for minimizing noise in regenerative resistors. These include improved construction methods and the use of low-noise materials.

VI. Regulatory Standards and Compliance

A. Overview of Relevant Industry Standards

Regenerative resistors must comply with various industry standards, such as those set by the IEC and Underwriters Laboratories (UL). These standards ensure that resistors meet specific safety and performance criteria.

B. Importance of Compliance for Safety and Performance

Compliance with industry standards is crucial for ensuring the safety and reliability of regenerative resistors. Non-compliance can lead to failures and safety hazards, making it essential for manufacturers to adhere to these regulations.

C. Recent Changes in Regulations Affecting Regenerative Resistors

Recent changes in regulations have focused on improving the safety and environmental impact of electronic components. Manufacturers must stay informed about these changes to ensure compliance and maintain market competitiveness.

VII. Future Trends and Innovations

A. Emerging Technologies in Regenerative Resistor Design

The future of regenerative resistors is likely to be shaped by emerging technologies, including advanced materials, smart sensors, and integrated designs. These innovations will enhance performance and open new avenues for applications.

B. Predictions for the Future of Regenerative Resistors in Various Applications

As industries continue to prioritize energy efficiency and sustainability, the demand for regenerative resistors is expected to grow. Their role in electric vehicles, renewable energy systems, and advanced electronics will become increasingly critical.

C. The Role of Sustainability and Eco-Friendly Materials

Sustainability is becoming a key consideration in the design and manufacturing of regenerative resistors. The use of eco-friendly materials and processes will not only reduce environmental impact but also appeal to environmentally conscious consumers.

VIII. Conclusion

Understanding the latest specifications and advancements in regenerative resistors is essential for engineers and designers working in various industries. As technology continues to evolve, regenerative resistors will play a crucial role in enhancing energy efficiency and performance. The future holds exciting possibilities for these components, and ongoing research and innovation will undoubtedly lead to further advancements in this field.

IX. References

- [1] International Electrotechnical Commission (IEC) Standards

- [2] Underwriters Laboratories (UL) Compliance Guidelines

- [3] Recent Advances in Resistor Technology: A Review

- [4] Emerging Trends in Power Electronics: The Role of Regenerative Resistors

- [5] Sustainable Materials in Electronics: A Comprehensive Overview

This blog post provides a detailed exploration of the latest specifications and advancements in regenerative resistors, ensuring a thorough understanding of their importance in modern technology.